Cold storage construction is one of the fastest-growing sectors in the construction industry, driven by increasing demand for perishable goods and industrial needs. According to Vantage Market Research, the global cold storage market is projected to reach $38 billion by 2030, growing at a 13.6% CAGR from 2023 to 2030.

As the sector evolves, so do the challenges. In this blog, we’ll address the most pressing concerns for cold storage owners and operators today and show how ARCO Design/Build is not only meeting these challenges but delivering peace of mind with tailored, future-proof solutions that ensure your business is built to thrive in an ever-changing market.

Why Partner with ARCO Design/Build for Cold Storage Projects?

At ARCO Design/Build, we understand that cold storage facilities are more than just buildings – they are vital to the success of your business. Our approach stands out because we offer the following:

- Specialized Expertise: A deep understanding of cold storage requirements to meet your unique operational needs.

- Design-Build Efficiency: Streamlined processes that save you time and provide cost certainty so you can move forward with confidence.

- Innovative Solutions: Custom designs focused on scalability, energy efficiency, and sustainability aligned with your long-term goals.

We do more than build exceptional facilities; we deliver lasting solutions that empower your business to grow, adapt, and succeed in an increasingly competitive market. Partner with ARCO Design/Build to turn your cold storage challenges into opportunities, giving you the confidence and peace of mind to focus on what matters most – your business’s continued success and future growth. Learn more about our cold storage solutions.

Ensuring Cost Certainty in Cold Storage Construction

Economic volatility, inflation, and material shortages create cost uncertainties in cold storage design and construction. Let’s dive into the factors at play and how ARCO addresses them.

Addressing Cost Fluctuations

Material price volatility, labor shortages, and evolving regulations can unexpectedly escalate costs. For example, insulated metal panels and refrigeration systems often experience price surges due to supply chain disruptions.

ARCO’s Lump Sum Pricing Approach

To ensure budget predictability, ARCO employs a lump-sum pricing model, offering:

- Cost Certainty: A fixed project price protects you from unforeseen expenses.

- Comprehensive Scope: All-inclusive pricing from design through construction.

- Risk Transfer: We absorb market risks, ensuring financial stability for clients.

This approach is especially valuable in cold storage, where per-square-foot costs are higher than traditional warehouses, helping you avoid change orders and budget overruns.

Managing Risks in Cold Storage Projects

Cold storage projects come with their own set of risks, from material cost fluctuations to supply chain disruptions and evolving regulations. Here’s how ARCO minimizes these challenges.

ARCO’s Risk Mitigation Strategies

Our design-build approach reduces risk by transferring financial and operational responsibilities to ARCO. Key benefits include:

- Financial Protection: We shield clients from cost overruns due to market fluctuations.

- Schedule Assurance: Our team ensures that your project stays on track, avoiding costly delays.

- Quality Control: We maintain rigorous oversight to ensure consistent quality throughout the project.

- Streamlined Process: With a single point of contact and a unified team, we simplify every step of the project, ensuring clear communication and eliminating unnecessary complexity.

By working with ARCO, clients can proceed with confidence, knowing your project risks are being managed by the most experienced professionals.

Energy Efficiency and Sustainability in Cold Storage

With rising operational costs and growing environmental concerns, energy-efficient designs and sustainable construction practices are quickly becoming industry standards. Here’s how ARCO integrates these trends.

Innovations Driving Energy Efficiency

Businesses are increasingly adopting energy-saving innovations, such as:

- Advanced Insulation Materials: Improve temperature retention and reduce energy consumption.

- High-Performance Refrigeration Systems: Deliver precise cooling while minimizing energy use.

- IoT-Enabled Temperature Controls: Provide real-time monitoring and optimization of energy consumption.

ARCO’s Commitment to Sustainability

ARCO is committed to helping clients achieve sustainable facilities by:

- Incorporating Green Building Techniques: Reduce energy consumption and environmental impact.

- Designing for Long-Term Efficiency: Including renewable energy and water conservation systems.

- Achieving Green Certifications: We help clients meet LEED or other green certifications, aligning with both environmental and business goals.

The Role of E-Commerce in Driving Cold Storage Demand

The rise of e-commerce and online grocery shopping has fueled an explosion in cold storage demand. ARCO is helping businesses meet these demands with scalable and efficient designs.

ARCO’s Scalable Solutions for E-Commerce Growth

We provide solutions to meet the increased demand for fast, reliable cold storage:

- Tailored Designs: We build facilities optimized for high turnover and efficient product flow.

- Scalability: We design facilities that can grow alongside your business needs.

- Advanced Technologies: Integrating automation and robotics to seamless operations.

These solutions ensure your cold storage facility can keep pace with the growth of e-commerce.

Managing Extended Lead Times for Building Materials

Supply chain disruptions have extended lead times for critical materials in cold storage construction. Here’s how we keep projects on schedule.

ARCO’s Proactive Procurement Strategies

We mitigate these challenges through:

- National Buying Power: Leveraging supplier relationships for priority access to materials.

- Early Procurement: Ordering long-lead time items during the design phase to avoid delays.

- Strategic Sequencing: Aligning material deliveries with project milestones to minimize downtime.

- Alternative Sourcing: Diversifying supplier networks to ensure materials are available when needed.

These strategies ensure timeline delivery and minimize construction delays.

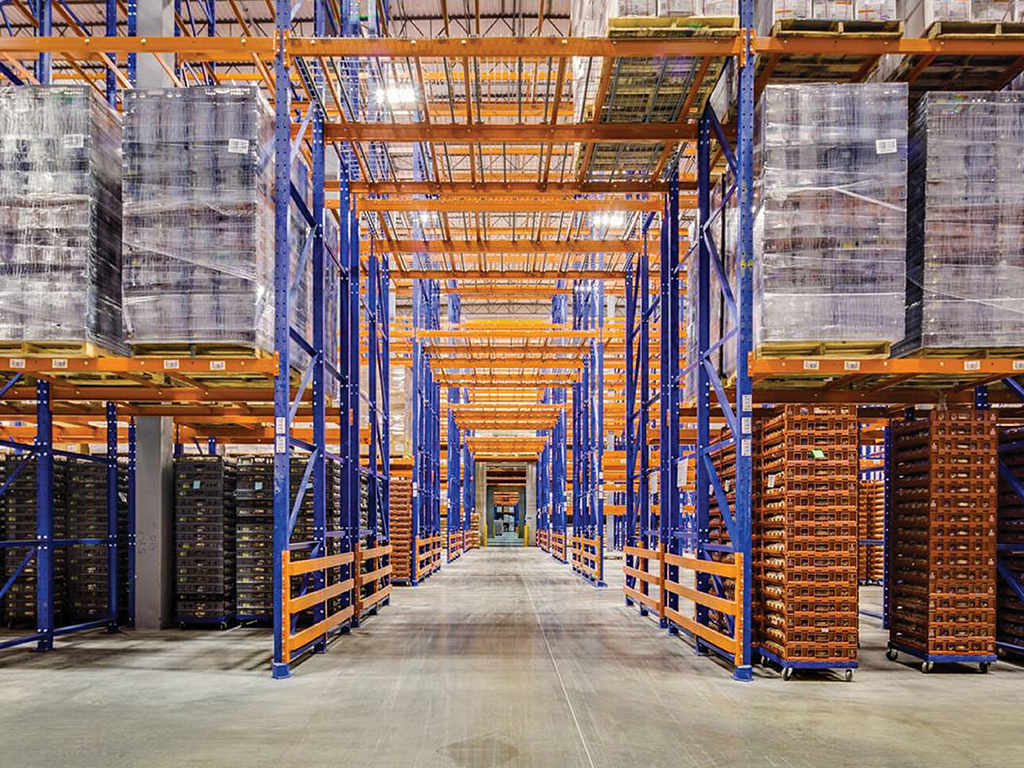

Maximizing Inventory Management in Cold Storage Facilities

As demand for cold storage grows, optimizing existing facilities has become essential. ARCO offers solutions to help businesses maximize their current infrastructure.

ARCO’s Optimization Solutions

We help businesses optimize their existing cold storage facilities by:

- Facility Expansion: Repurposing existing spaces to accommodate more inventory.

- Mobile Racking Systems: Enhancing space utilization and reducing cooling costs.

- Vertical Storage Solutions: Leveraging high-bay designs to increase storage capacity.

- Advanced Inventory Management: Integrating cutting-edge warehouse management systems (WMS).

These solutions enable clients to meet rising demands efficiently without extensive new construction.

Conclusion: Building the Future of Cold Storage with ARCO Design/Build

Cold storage facilities are more than just structures—they are the foundation for your business’s growth and success. At ARCO Design/Build, we understand the stakes and provide tailored solutions that address both today’s challenges and tomorrow’s opportunities. Our commitment to cost certainty, risk mitigation, and sustainable design ensures that your facility is not only built to last but also built to evolve with your needs.

By partnering with ARCO, you gain more than just a construction team; you gain peace of mind knowing your project will be delivered on time, on budget, and with the flexibility to grow. We’re here to support your long-term success with innovative, future-proof cold storage solutions to help your business thrive.

Contact ARCO Design/Build today to discover how we can help you build a cold storage facility that stands the test of time.