The Mid-South’s aviation market is booming – and struggling to keep up. Joel Olson, Vice President of ARCO Design/Build’s Memphis office, explains why traditional construction methods can’t meet the moment, and what a design-build approach changes for airport operators, FBOs, and MRO providers.

The numbers tell a stark story. The global aviation facilities market is racing toward $1.13 billion by 2033, up from $797.59 million today. North America drives over a third of that demand – and nowhere is the pressure more acute than the Mid-South. In Tennessee alone, 79% of airports report hangar waitlists that stretch for months. Memphis and Nashville lead the region’s demand for modern aviation infrastructure.

Every month those waitlists grow longer represents lost revenue. Every delayed project means ground aircraft, deferred maintenance, and missed opportunities. Yet aviation continues building facilities with methods designed for an era when speed didn’t matter and operational efficiency was an afterthought.

Where Industrial Strength Meets Aviation Precision

ARCO Design/Build brings something different to aviation construction – nearly four decades of building complex manufacturing and industrial facilities where operational efficiency determines profitability. We’ve learned what aviation is discovering: when facilities directly generate revenue, traditional construction approaches become expensive liabilities.

In distribution centers, we’ve seen how design determines how quick products move through the facility. In manufacturing plants, we know layout drives production speed. Aviation facilities face the same reality – your hangar layout determines maintenance speed, your FBO design shapes passenger experience, your door placement affects your entire operation.

The parallel is clear: aviation facilities aren’t just buildings. They’re operational assets that demand builders who understand operations.

Why Design-Build Changes the Aviation Equation

The traditional design-bid-build approach to aviation construction fragments accountability across multiple contracts. Architects design in isolation. Contractors bid on incomplete plans. Airport authorities referee disputes while projects stall. When foam suppression requirements emerge mid-construction or FAA compliance issues surface during permitting, fingers point in every direction except toward solutions.

Design-build eliminates this coordination chaos entirely. No more contractor finger-pointing. No more architect-builder disputes. No more playing referee while your project stalls. Instead: one contract, one team, one accountable partner managing the entire delivery from concept through completion.

But here’s what actually matters to your operation: Design-build delivers measurable business value:

-

-

- Cost certainty from day 30: Know your real number before you’re committed, not after bids shock your budget

-

- Change orders below 1%: While design-bid-build projects average 5-8% cost growth through changes

-

- 30% schedule compression: Because design and construction happen in parallel, not in sequence

- Zero finger-pointing: When issues arise, one partner owns the solution

-

Consider what design-build accountability delivers for each aviation segment:

For FBO Operators: Your passenger experience vision translates directly into reality. No interpretation losses between architect and contractor. Your competitive differentiation – whether luxury amenities or operational efficiency – drives every decision from initial design through final inspection, with a single accountable partner ensuring your vision becomes reality.

For MRO Providers: Maintenance workflow drives layout decisions from day one, not after concrete is poured. Bay configurations match your actual aircraft mix. Tool placement reflects your technician movements. Parts flow follows your inventory system. The result: facilities that accelerate maintenance velocity instead of constraining it.

For Corporate Flight Departments: Design-build balances competing demands – security and accessibility, prestige and functionality, efficiency and image – through integrated decision-making. Your executives get facilities that reflect corporate standards while your flight crews get operations that actually work.

For Regional Airports: Faster project delivery means capturing revenue sooner. When new hangar capacity comes online 10 weeks early, that’s 10 weeks of lease revenue you don’t leave on the table. When construction disputes disappear, your staff manages operations instead of contractor conflicts.

Designing Facilities That Generate Revenue, Not Just House Aircraft

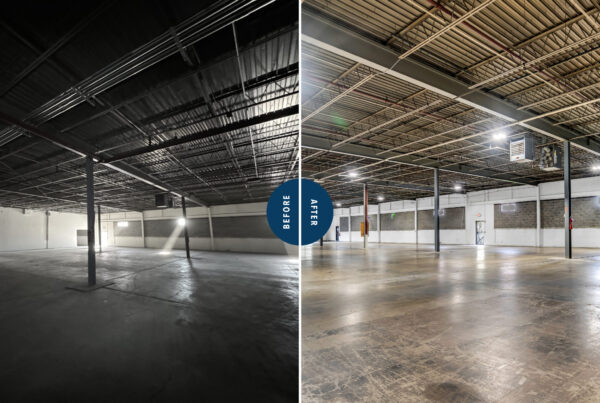

The expertise gap in aviation construction is real. Too many firms treat hangars like warehouses with bigger doors. They miss the operational nuances that determine whether facilities become profit centers or cost burdens.

Early engagement changes the entire trajectory. When operational leaders join design discussions from the start, facilities emerge that actually drive revenue:

-

-

- Maintenance bays that reduce turn times by optimizing technician movement

-

- FBO layouts that increase fuel sales through strategic positioning

-

- Corporate facilities that enhance company image while controlling costs

- Support systems engineered for aviation’s specific demands – not adapted from other industries

-

Real-time cost modeling during design transforms budgets from wishes into commitments. Value engineering focuses on operational optimization that pays dividends for decades, not corner-cutting that creates problems for years.

Unliked firms that outsource design to architects unfamiliar with aviation requirements, we work with dedicated design partners who have delivered alongside us for years. Your structural engineer understands hangar door loads. Your architect knows foam suppression implications. That shared experience eliminates the coordination gaps that plague traditional delivery.

Speed to Revenue: The 4-10 Week Advantage

Speed without precision means nothing in aviation. Precision without speed means lost opportunity. Design-build delivers both.

Our approach compresses timelines by 30% compared to design-bid-build – typically 4 to 10 weeks faster than standard aviation projects. The difference isn’t about rushing. It’s about eliminating the sequential gamble that plagues traditional delivery.

In design-bid-build, the path looks like this: architects complete detailed drawings over months. You go out to bid hoping the design fits your budget. Bids come back over budget – which happens more often than not. Now you’re redesigning, rebidding, and watching weeks turn into months of delays before construction ever starts.

Design-build eliminates that cycle entirely:

-

-

- Feasibility confirmed early: We validate what’s buildable within your budget before significant design investment

-

- Cost certainty before commitment: You know your real number while there’s still time to optimize, not after bids shock your budget

-

- Parallel progress: While contracts are signed and construction mobilizes, design refinement and permitting happen simultaneously – managed by one team, not handed of between strangers

- Long-lead materials ordered early: Critical components are in motion based on preliminary decisions, not waiting for final specifications

-

The result: your project advances on multiple fronts while traditional projects wait in sequential queues.

The Regional Opportunity

The Mid-South aviation market stands at an inflection point. Memphis International Airport processes more cargo than almost any facility globally. Nashville’s corporate aviation traffic surges with the city’s growth. Regional airports from Jackson to Little Rock scramble to meet demand.

Yet few construction partners understand both aviation’s unique demands and the regional market’s specific dynamics. National firms lack local relationships. Local contractors lack aviation expertise. The market needs partners who bring industrial-scale capability with regional commitment.

Your Next Competitive Advantage

Your hangar capacity won’t grow by itself. Your competitors aren’t waiting. And your clients expect more speed, more service, and more space.

While competitors debate delivery methods, you could be generating revenue. While they manage contractor disputes, you could be optimizing operations. While they explain delays to stakeholders, you could be capturing market share.

ARCO Design/Build brings nearly four decades of integrated project delivery to aviation. We don’t just understand construction – we understand how operationally critical facilities create competitive advantage.

From FBO expansions to full aviation campuses, we deliver speed-to-market, cost certainty, and a true partnership that turns capital investment into lasting advantage.

Let’s explore how design-build can transform your next aviation project from a capital expense into a competitive advantage.

One partner. Real accountability. Measurable results.